By: Pierre van der Eng

Van Leer was a Dutch company producing metal and later also plastic drums and pails for packaging and storage. Founded by Bernard van Leer, it started operations in Amsterdam in 1919 as Van Leer’s Vereenigde Fabrieken NV. Before World War II, it internationalised operations by establishing subsidiaries across Europe.

After the war it established subsidiaries in the USA, South America, Africa and Asia. Its main foreign subsidiary was Metal Containers Ltd in the United Kingdom, which itself established and operated Van Leer’s sub-subsidiaries in current or former British colonies. By 1960 the company had subsidiary ventures in The Netherlands and in at least 21 other countries and it employed around 5,500 worldwide

Through Metal Containers, Van Leer considered establishing operations in Australia during the 1950s. But it took until 1958 before the first steps were taken. John Charles Prichard (1921-2015) was the production manager at Metal Containers who intended to return to his native Australia in 1958. Prichard had been involved in organising the establishment and operation of subsidiaries in Tanjung Priok (Indonesia), Singapore and Malaya. The company’s Managing Director, Oscar van Leer, son of the founder, asked him to identify the opportunities and risks of the company starting operations into Australia.

The aim was to produce medium to large steel drums and steel drum closure systems for use in Australia’s mining, oil and chemical industries. Prichard researched Australia’s market for metal drums and pails and the availability of suitable steel sheets. He concluded that the market for pails in Australia was for 75% dominated by Rheem Australia Pty Ltd. This 1936 local subsidiary of American company Rheem had factories in all capital cities in Australia, except Tasmania.

There were a few smaller producers of pails in Sydney, Townsville and Adelaide, but Rheem was the only producer of large and medium sized steel drums in Australia. Rheem Australia was a joint venture are 50%-owned by Australian steel producer BHP. For its production of drums, the company depended on steel sheets produced by Australia’s only cold rolling mill, Lysaght’s Works Pty Ltd in Newcastle. In turn, Lysaght depended on supplies of steel from the BHP steel mill in Newcastle. The BHP-Lysaght-Rheem combine had a near-monopoly in Australia’s market for medium and large steel drums, because imports of drums and metal sheets were subject to import tariffs.

Prichard and Van Leer agreed that a joint venture was ‘the least risk option’ to enter the Australian market. Prichard checked out potential partners and settled on J. Gadsden Australia Ltd, a well-known manufacturer of tin cans for foodstuffs, oil, kerosene, paint etc. Gadsden’s was a sizeable enterprise with factories in different parts of Australia, which in 1954 had become an A₤4 million public company.

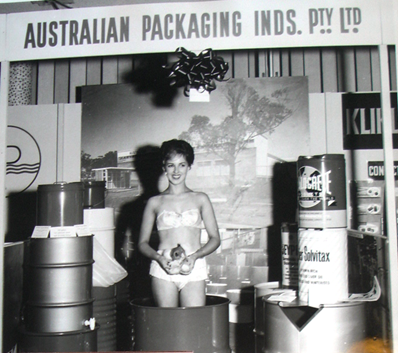

There were two other reasons to focus on Gadsden’s. It had recently established ‘a sizeable pail operation in Sydney’. More importantly, as a customer of Lysaght for steel sheets, ‘they had some clout with BHP and John Lysaght respectively … to a degree [that] would counter the fact that 50% of Rheem was owned by BHP’. Van Leer entered negotiations with Gadsden’s, and in March 1960 both signed a 50% joint venture agreement. It established Australian Packaging Industries Pty Ltd (API), which was incorporated in Canberra with A₤1 million capital. Prichard was API’s Managing Director until he returned to the UK in 1975.

Source: Van Leer Archive, Gemeentearchief Amsterdam.

API engaged in discussions with Lysaght, which initially promised to supply sheet steel. Lysaght then reneged, probably on instructions from BHP to protect the interests of Rheem Australia. In addition, the Rheem subsidiary reminded its customers to live up to the letter of their existing contracts, i.e. not buy steel drums from API.

During 1961 API absorbed the nascent pail production facility of Gadsden’s, imported second hand machinery for medium and large steel drum production from Van Leer in The Netherlands to start production. It also imported steel sheets from The Netherlands and the United States. The American steel was of such bad quality that Gadsden started to mistrust the ability of Van Leer to operate API. Van Leer took legal action in the United States on behalf of API. It won the case in 1962, which minimised losses due to the limited drums and pails it could produce. Although Lysaght started to deliver small quantities of surplus steel sheets, API sustained losses during its first few years.

Source: Van Leer Archive, Gemeentearchief Amsterdam.

API’s financial situation turned around in 1965, when it paid its first dividend. Two factors caused the turnaround. Firstly, API started to import competitively priced steel sheets of a suitable quality from Japan, despite objections from its supplier Lysaght. Secondly, Rheem’s contracts for the delivery of drums with its customers started to expire, allowing them to start ordering drums from API. A major step forwards was in 1966, when Shell ordered 20,000 petrol containers, which was followed by other large orders from other previously Rheem-only customers.

API was from the outset a sizeable operation. During 1960-1961 it built two new drum factories in Chester Hill (NSW) and North Altona (Victoria). It then expanded by building four further drum factories in Perth in 1966, Brisbane in 1968, Townsville in 1974 (to produce drums for Queensland Nickel Pty Ltd) and Seven Hills (NSW) in 1975. With this expansion, its administrative NSW headquarters in Chester Hill became too small and moved to South Granville in 1963. In Victoria, the company moved its offices from Altona to Epping.

Despite this expansion, the relations between the two joint venture partners remained poor during the 1960s. This was partly due to the losses API sustained in the early-1960s. The main reason was the incompatible personality of API’s two main board members: the insecure and abrasive Norman C. Gadsden (1895-1973) from Toorak in Melbourne and the experienced and suave Oscar van Leer (1914-1996) from Amsterdam (Johannes 2009). In 1957, respectively 1958, both had become MDs of the companies their fathers had established. Gadsden blamed Van Leer for API’s losses in the early-1960s, when the Gadsden parent company also suffered loss of income.

A partial solution was for API’s board to have more independent directors. But the air did not clear until Norman Gadsden’s passing in 1973. His nephew and successor Ronald Gadsden, proved more congenial from Van Leer’s perspective. In November 1975 Van Leer bought the 50% of API shares held by Gadsden’s, paying A$2.4 million. The company was subsequently renamed Van Leer Australia Pty Ltd.

In 1975, the Van Leer parent company in The Netherlands suffered its first only ever loss due to the fallout of the 1973 oil crisis. In response, its board agreed to Oscar van Leer’s proposal to diversify the company’s operations and thus reduce its dependence on the oil and petrochemical industries. It diversified into the production of plastic and fibre-based drums, and of industrial strength films. It also invested in research and development, leading to product innovations in the packaging industry.

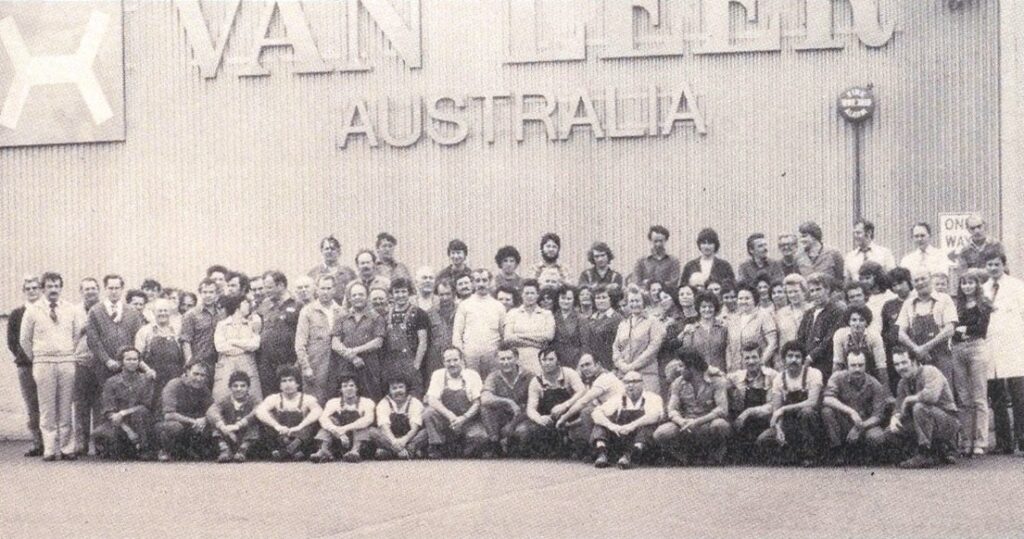

Van Leer Australia Pty Ltd followed the lead of its parent. It diversified further from steel pails and drums into plastic medium sized drums and specialised plastic containers. It acquired Johnstone Plastics Pty Ltd in Silverwater (NSW) in 1980, which manufactured blow-moulded bottles for the pharmaceutical, toiletries and cosmetic industries. This company was renamed Van Leer Food Packaging Pty Ltd. Including Johnstone, Van Leer Australia had around 350 employees across Australia in 1980.

Source: Murray Art Museum Albury LibraryMuseum.

In 1986 Van Leer Australia Pty Ltd acquired food packaging company APM Fibrecraft Pty Ltd, which it renamed VLA Fibrecraft Pty Ltd and later absorbed into Van Leer Food Packaging Pty Ltd. This venture had two factories in Marayong (NSW) and Doncaster (Victoria). Van Leer Australia Pty Ltd also developed two divisions for flexible and medical plastic products. The latter produced plastic hypodermic syringes and filters (Van Leer 1980). And in 1992 Van Leer Australia Pty Ltd built a new $6 million foam polystyrene food packaging plant in Albury, employing 60.

In 1999 Huhtamaki Oyi (Finland) acquired Van Leer in The Netherlands. The company in Australia continued as Huhtamaki Van Leer Pty Ltd in 2000, but a year later Huhtamaki sold the global Van Leer operations to US packaging multinational Greif Brothers. The Australian operation was taken over by Greif Australia Pty Ltd in 2001 and the name Van Leer disappeared worldwide. In 2007 Greif sold all former Van Leer operations in Australia to Drum Makers Pty Ltd, a subsidiary of the Visy group, then controlled by Visy Industrial Packaging Holdings Pty Ltd of Australian entrepreneur Richard Pratt.

The only reminder of Van Leer’s operations in Australia is the Van Leer Foundation. It provides financial support for projects that benefit young children, caregivers and communities around the world. In 1966 it made its first donation to the ‘Slow Learners Children Group’, a West Australian community initiative. It has since supported various early childhood community initiatives in Australia, particularly those benefiting Aboriginal children.