Temporary display at Juliana Village, Miranda, Sydney – April 2024

Philips Electronics Pty Ltd

Pierre van der Eng

The predecessor of Philips Electronics Pty Ltd in Sydney was one of the largest Dutch companies that operated in Australia. In 1970 when it had 13,000 employees in various locations in Australia. The company was well-known for the branded lighting and consumer electronic goods which it produced in Australia.

The firm’s parent company, NV Philips Gloeilampenfabrieken, was established in 1891 in The Netherlands to produce electrical incandescent lamps. Already in 1901 did the company’s lamps find their way to Australia, where electrification had started in the capital cities and the market for electrical incandescent filament lamps had started to grow. Since then, the company’s business contacts with Australia expanded. It is possible to identify six stages in this process.

1912-1925

In 1912, the Philips company sent its foreign sales representative Aloys Bakker on a global tour to accumulate foreign orders for incandescent lamps. In Australia, Bakker assessed the market for lamps, acquired orders and established contacts with potential agents. The company’s lamp exports increased significantly during World War I, when Australia’s lamp imports from the UK decreased. Philips appointed wholesalers Lawrence and Hanson Ltd and Warburton, Franki Ltd as its agents in Australia.

1925-1940

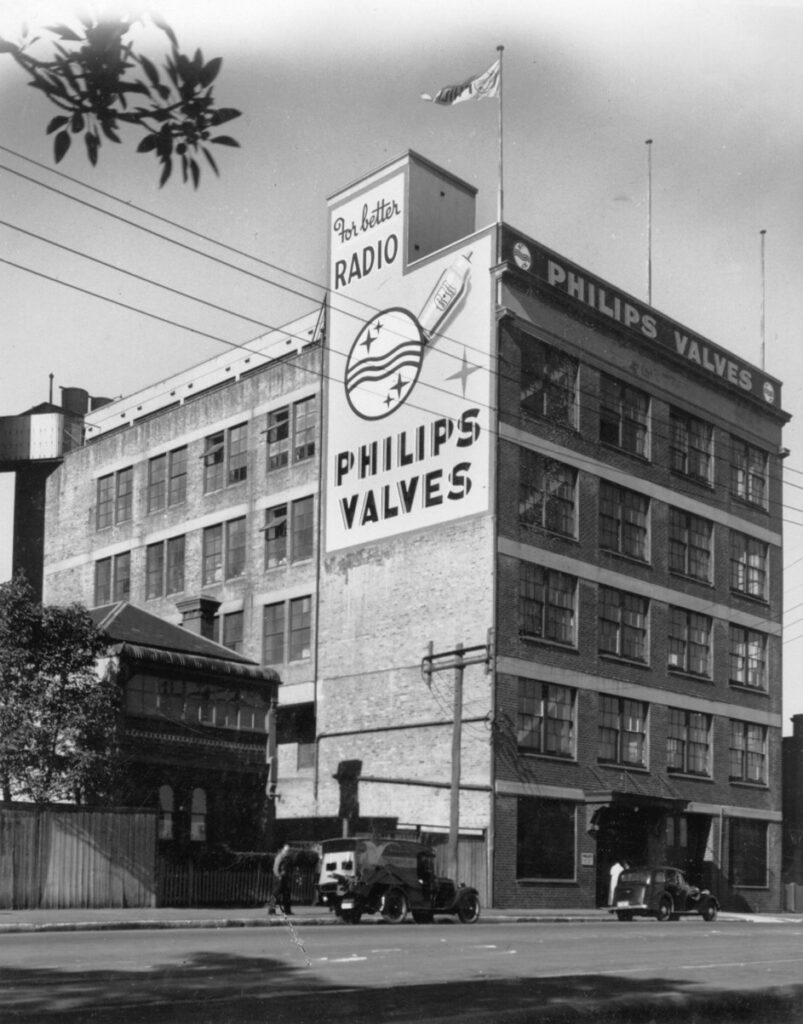

Since the early-1920s, Philips in The Netherlands diversified its production towards radio broadcasting equipment and a growing array of electronic components. Radio amateurs used those, particular radio valves, to build their own radio receivers. Soon the company also exported Philips-branded radio receivers to Australia.

Exports to Australia increased so quickly that in 1925 the company sent Anton den Hertog to Australia to establish a subsidiary company to import Philips products. Den Hertog assumed control of the imports of Philips products. Together with the company’s two agents, he incorporated Philips Lamps (Australasia) Pty Ltd in December 1926 with himself as Managing Director (CEO). The company changed its name in later years. The last change was in 1994 to Philips Electronics Pty Ltd, also known as ‘Philips Australia’.

In the 1920s, The Australian government encouraged import-replacing industrialisation in order to reduce the use of the country’s export earnings from wool and other commodities to be able to pay off Australia’s relatively large foreign debt. This took the form of import tariffs, which encouraged manufacturing companies to produce goods in Australia.

Tariff increases for radio receivers (1929), lamps (1931) and radio valves (1937) encouraged Philips to establish factories in Australia. The first factory was established 1931 by Electric Lamp Manufacturers (Australia) Pty Ltd (ELMA) in which Philips was the leading joint venture partner. ELMA’s factory in Newcastle produced the lamps which Philips Australia marketed. Profits from the lamp business supported the operations of other Philips factories in Sydney. Philips Australia employed 663 in 1940, mainly in Sydney.

1940-1945

The World War II years could have been a period of expansion for Philips Australia. Instead, it fell under the suspicion of Australia’s nascent secret service after the war broke out in September 1939. Its Dutch CEO Armand Giberius was detained and in 1940 expelled from Australia on spurious grounds.

The Philips factories in continental Europe continued to operate during the 1940-1945 German occupation, under the direction of the parent company in The Netherlands. All Philips companies outside Europe, including in Australia, continued operations under the management of a separate company headquartered in the unoccupied Netherlands Antilles.

This arrangement nurtured further allegations against Philips Australia. The company experienced significant difficulties. It was unsuccessful in tendering for lucrative defence-related contracts. After his appointment in 1942, new Dutch CEO Frank Leddy gradually turned the situation around.

1945-1970

Leddy was CEO of Philips Australia until 1962. During his tenure, the company experienced significant growth and diversification. Its employment increased fivefold to 3,500 in 1960. There were two main reasons for this postwar expansion.

Firstly, high inward migration and rising wages in Australia. Both increased markets for a growing variety of electrical and electronic goods. Philips Australia produced many of these goods, using the product and production technologies developed by its parent in The Netherlands. Most of these products were produced at the large factory complex in Hendon near Adelaide to which the company relocated all its Sydney-based manufacturing operations in 1946.

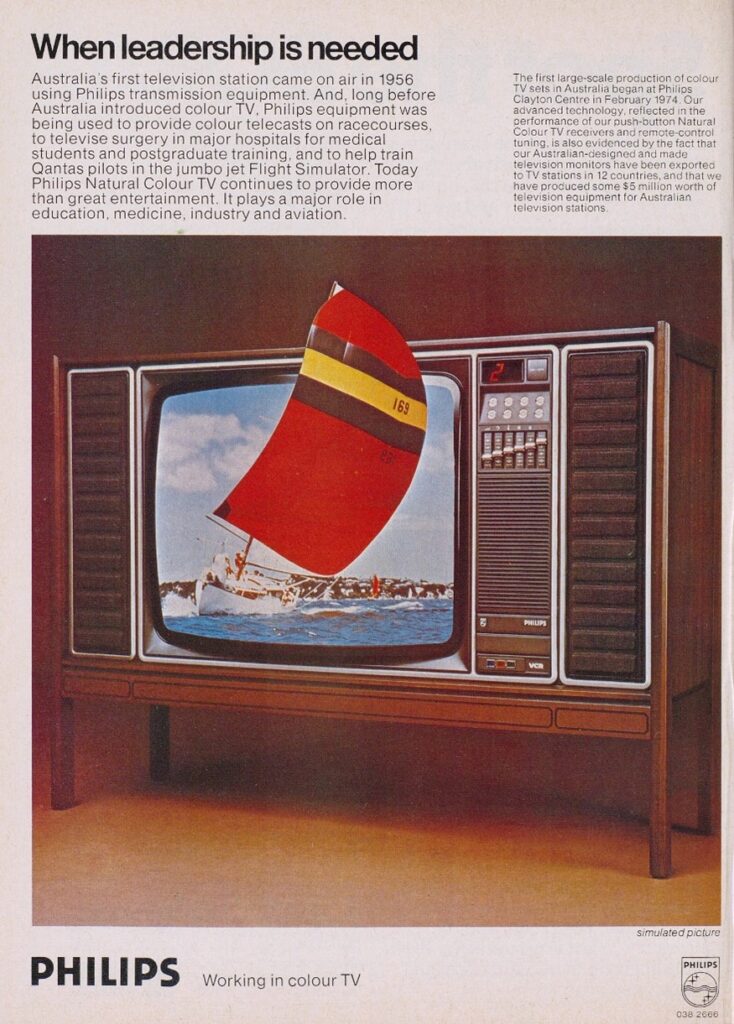

Secondly, the company’s production of components for the relatively large number of radio producers in Australia was particularly lucrative. After Australia in 1956 introduced television, these firms also required television components, such as the television tubes Philip produced in Hendon, to assemble television sets. This high profitability allowed Philips Australia to expand and diversify its operations by acquiring various local companies or establishing new ones.

1970-1990

The largest acquisition in 1969 involved the Melbourne-based Electronic Industries Ltd (EIL). This large company produced and traded electrical products under various brand names, including Astor radios and televisions. It was an important customer for the electronic components Philips produced in Hendon. But in 1969 EIL was in major financial difficulties. Philips Australia did not want to lose EIL as a customer.

In addition, Philips in The Netherlands had in 1967 acquired competitor Pye of Cambrdge Ltd in the UK, including its Melbourne subsidiary Pye Industries Pty Ltd. The latter had a 40% interest in EIL. The Philips parent company wanted to avoid EIL’s financial difficulties cascading via Pye in Melbourne and Pye in Cambridge to Philips in The Netherlands. The solution was to require Philips Australia to merge with EIL.

In 1970, Philips Australia absorbed all of EIL’s employees and subsidiary companies. Its employment more than doubled from 5,797 in 1969 to 13,000 in 1970 and its subsidiaries doubled from 37 to 74. New Dutch CEO Herman Huijer faced the task of selling or closing the many loss-making companies inhesited from EIL. He continued this difficult task after Philips Australia also absorbed the Pye Australia group in 1977.

Huyer’s tasks became more difficult when the Australian government in 1973 started reductions of the import tariffs that sustained many of Philips Australia’s manufacturing operations. This contributed to lowering the company’s financial performance. In response, the company reduced its operations in Hendon and eventually sold the large plant in 1980. Australia’s switch to colour television (CTV) in 1975 offered some solace due to a surge in demand for CTV tubes and CTVs, which Philips Australia produced in its new Clayton factory.

During the 1970s, CEO Huyer sought to transform Philips Australia into the Philips regional headquarters in the Asia Pacific region. A leading role for Philips Australia in marketing and R&D would allow it to shed shedding low value work to Philips subsidiaries in Asian countries with lower labour costs, while retaining high value positions. However, the parent company was preoccupied with integrating its much more substantial operations across Europe in the context of the process of European economic integration. It largely left Philips Australia to its own devices.

By 1980, Philips Australia still employed 5,504. Facing the threats of increased imports of consumer electronics from Japan and further reductions in Australia’s import barriers, new Dutch CEO Willem Maclaine Pont tried to leverage the parent company’s defence-related competencies in order to sustain the Australian operations. Nevertheless, the trend continued and more Philips factories in Australia slimmed down or shut their doors. By 1990, Philips Australia employed 2,900.

1990-now

In the early 1990s, Philips Australia transformed into a company that imports and markets Philips products. Initially, the Philips-branded products were produced by its sister companies around the world. However, increasingly the parent company outsourced the production of Philips-branded products, such as lamps and consumer electronics, to OEM manufacturers in Asia, particularly in China.

In Australia, only ELMA bucked this trend by continuing to produce lamps and fluorescent tubes in Newcastle until it too closed in 2002.

This development led the Philips parent company to divest the production of its global lighting and consumer electronics products. In 2016, the lighting assets became Signify NV. The consumer electronics assets were sold in 2021. In 2023, they became Versuni Holdings BV. Both new companies retained the right to use the Philips brand name. The slimmed down Philips company focused on the production of lucrative health equipment and machinery, such as MRI scanners.

Philips Australia still sells lamps and consumer electronics under the Philips brand name, which are now supplied by Signify and Versuni. Its core business is the marketing and servicing of the medical equipment it acquires from its parent company. Philips Australia remains one of Australia’s 2,000 largest firms by turnover, but its employment decreased to 569 in 2021.

In 2000 the company led the technical implementation of the lighting display at the Sydney Opera House.

See also:

Philips factory in Newcastle produced almost all Australia’s electric lamps for 70 years

Frans Leddy reorganised Philips Australasia

Turning Adversity into Opportunity: Philips in Australia, 1945-1980